aisc oversized holes - bolt hole size chart : 2024-11-01 aisc oversized holes There’s no need for oversized holes with expansion bolts. Adhesive anchors however require a drill bit larger than the bolt diameter – and this requires . aisc oversized holesFind information about and book an appointment with Dr. Mark B Kabins, MD in Las Vegas, NV. Specialties: Orthopedic Surgery.

Next: 1548286784. Dongsi Lu a provider in 216 S Kingshighway Blvd Saint Louis, Mo 63110. Phone: (314) 362-5641 Taxonomy code 207ZP0102X with license number 2004009701 (MO) and 33 years of experience. Provider is enrolled in PECOS Medicare. Insurance plans accepted: Medicaid and Medicare.

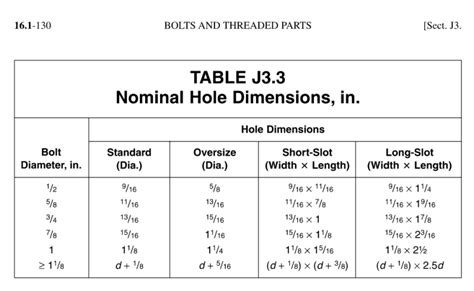

aisc oversized holes Oversized holes (OVS): These holes are larger than the diameter of the bolt and are used for connections that require high bolt tension. The larger hole allows .states that a hole 3/16” greater is an oversize hole. Is there any publica-tion, paper, etc. that addresses this subject? A: Enlarging the holes is not stan-dard procedure but rather something that has to be approved by the SER. The hole becomes an over-sized hole after modification, and the change would have to be considered.The hole types recognized by the AISC and RCSC Specifications are standard, oversized, short-slotted, and long-slotted, with nominal dimensions as given in the AISC Specification Table J3.3.

aisc oversized holes

the University of Washington and a former AISC intern, and Leigh Arber ([email protected]) is a senior engineer with AISC. Slip-critical connection required Slip-critical connection NOT required Joints that use oversized holes Joints that are subject to fatigue load with reversal of the loading direction Joints that use slottedLc = clear distance between the edge of the hole and edge of the adjacent hole or t connected part parallel to the applied force, in. L. = distance from the end of the connected part to the center of the hole, in. p. = force that a single connector exerts on the connected part, kips PI'. = force required to elongate the bolt hole 1/4 in., kips The washer requirements for this situation are found in Table 6.1 in the AISC 13th Edition, page 16.2-41, which is summarized below. ASTM Grade and Diameter Hole Type in Outer Ply . and not an oversize hole, my assumption is that no oversized/thick washer is required. However, you might want to run this past your design or structural . Depending on the type of structural connection, through holes may be oversized if they are to contain a galvanized bolt after assembly. Section J3.2 of the AISC Manual of Steel Construction: Load and Resistance Factor Design (LRFD manual) states oversized holes are not to be used in bearing type connections.sions of standard, oversized, short-slotted, and long-slotted holes. If an actual dimension exceeds the tabulated maxi-mum, it must be treated as the next larger hole size. For example, a 13/ 16 in. by 1 ¼ in. slotted hoe for a ¾ in. diam-eter bolt must be treated as a long-slotted hole because it exceeds the maximum short-slotted hole size (13/hsc = is the hole factor, taken as 1.0 for regular size holes, 0.85 for oversized and short slotted holes, and 0.7 for long-slotted holes. Tb = minimum bolt pretension, taken as 70% of the bolt tensile strength. Equation (2) is used with factored loads, but is intended to prevent slip at the service load level. While I agree that the table is intended to be maximum hole sizes I would not recommend using 1/16" oversize holes in a base plate unless you want the concrete contractor to cry foul on construcability. Similar to JLNJ, I have justified smaller holes than max recommended, but never below 5/16" oversize unless absolutely necessary.The maximum sizes of holes for rivets and structural bolts are given in Table J3.3. These holes are classified as: i) Standard holes – 1/16 in. larger than the nominal bolt diameter ii) Oversized holes – not allowed in bearing-type connections iii) Short-slotted holes – allowed in both slip-critical and bearing-type

Yesterday changed the oil, and for the first time, read the entire brake fluid cap, and nowhere does it say DOT4 LV; it just says to use 'DOT 4', so not sure it's better to use LV than regular DOT4. Have a few questions: 1. Do our trucks really have DOT4 LV fluid? 2. If yes, what is the recommended change interval for that kind of fluid? 3.

aisc oversized holes